| FOOD AND BEVERAGE PRODUCTION APPLICATION

Adhere to international food safety regulations

Made of premium food-grade materials, our solutions stand at the forefront of quality and precision, adhering to the highest European food safety regulations (FDA-approved).

From the initial stages to the final phases of product delivery, every process matters. Our cutting-edge butterfly valves maintain seamless operations safely, efficiently, and in accordance with stringent regulations.

Our valves are crafted to navigate the specific challenges of food and beverage production. They facilitate seamless fluid management, guarantee compliance, and optimize system fluids by minimizing energy consumption while maintaining production efficiency, reducing downtime, and preventing contamination.

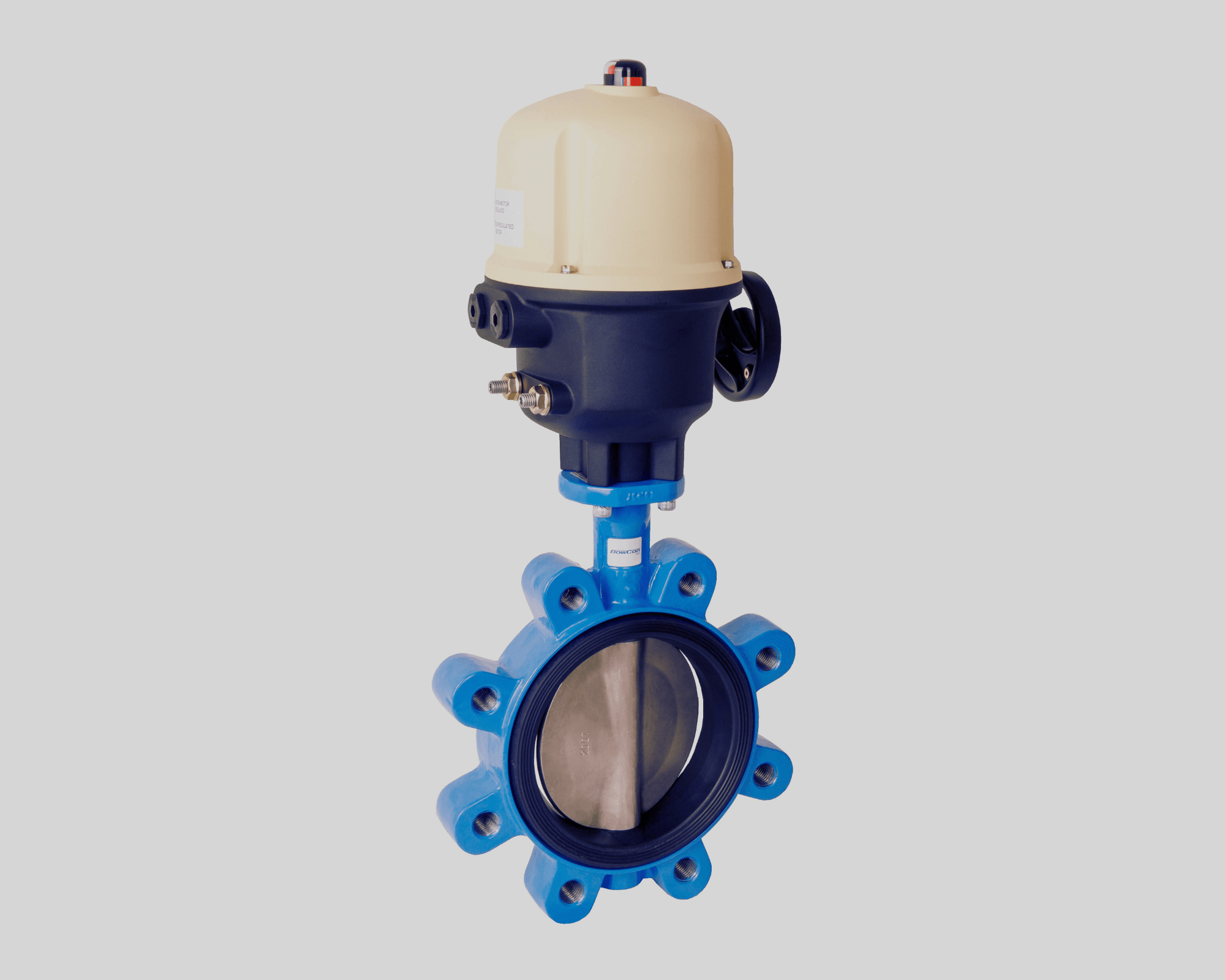

BUTTERFLY VALVES |

Praised for their versatility and efficiency, butterfly valves offer swift and effective regulation of flow across diverse applications, from HVAC systems to industrial processes.

✔️ Easy and fast operation

✔️ Excellent regulation and zero-leakage shut-off

✔️ Small and light in weight

| Key Features

Body type | Wafer design from size DN 25 to 2400 providing easy assembly and disassembly, with all the components interchangeable. A cost-effective solution that offers ease of installation between pipeline flanges, suitable for a variety of pressure levels.

Disc CF8M Construction | Crafted from high-grade polished CF8M material, the disc of our butterfly valves guarantees exceptional corrosion resistance and longevity, even in the most challenging environments.

Rubber Options in EPDM FDA, or NBR FDA | The choice of rubber in EPDM FDA or NBR FDA ensures superior sealing properties, safeguarding against leaks and ensuring reliable operation under varying pressures and temperatures, while also meeting stringent FDA regulations for food and beverage applications.

High-Performance Materials |

Our precision-engineered butterfly valves are constructed of premium Epoxy-Coated Ductile Iron, ensuring longevity and durability.

Operation Methods Options |

Our butterfly valves offer multiple operation methods, including manual levers, gears, and the highest-quality electric actuators.

This versatility allows operators to choose the most suitable operation method based on their needs, automation requirements, and control preferences.

Industry-Standard Certifications |

Aligned with European Industry Standards, our valves adhere to EN 588-2 for precise face-to-face dimensions and EN 1092-1 for accurate flange drilling. Designed by EN 593 specifications, they offer flexibility with metric or UNC bolting options. Thorough hydrostatic testing follows EB 12266-1 standards.

Furthermore, product testing complies with the European PED Directive No 2014/68/EU, dated 15/05/2014, ensuring quality and safety. With CE marking, our valves guarantee adherence to regulatory requirements.

This commitment to standards ensures effortless integration with existing infrastructure.

LET'S TALK

While we strive to provide you with comprehensive information, we understand that your specific application requirements may necessitate further details.

For inquiries, technical specifications, or to discuss customized solutions tailored to your needs, please don't hesitate to reach out — we're here to collaborate with you in enhancing your pharmaceutical handling processes with our premium butterfly valves.

Let's elevate your food and beverage applications together to optimize your handling processes with our premium butterfly valves.

Let's talk to begin the journey towards unmatched efficiency and reliability.

| Safety In Food and Beverage Production

Regulatory compliance is paramount in the dynamic landscape of food and beverage production management. Minimizing contamination risks, embracing quality control, and ensuring FDA approval underscore our commitment to producing precise valves.

Our FDA-approved butterfly valves guard efficiency, ensuring optimal flow distribution while safeguarding product quality and integrity and optimizing operational efficiency.

| Green transformation

Engineered for durability and reliability, our valves are built to withstand demanding food and beverage production environments.

With minimal maintenance requirements and long service life, our valves contribute to uninterrupted production and reduced downtime.

Our solutions optimize efficiency in the production process, reducing energy consumption, waste, and production costs contributing to sustainable goals.

By streamlining fluid handling and control, our valves help improve overall operational efficiency and productivity.

Join us in shaping the future of food and beverage production – where precision meets possibility and reliability knows no bounds.