| FILTRATION

Purify the world | one drop at a time

Specializing in providing top-tier filtration solutions, our valves ensure the purity and reliability of your fluid systems. Engineered with precision to deliver unparalleled performance, our Y-Strainers guarantee clean and safe media for various applications.

What are Y-Strainers?

Y-Strainers are essential components in water and other media filtration systems, designed to remove unwanted debris and particles from your pipelines. They are named for their Y-shaped design, which allows for efficient and effective filtration while maintaining a steady flow of fluid.

Y-Strainers | Key Features

→ High-Quality Construction

Built with robust materials to withstand harsh environments and ensure longevity.

→ Precision Filtration

Equipped with robust filtration screens, mesh-type or perforated-type that capture particles according to the requirement of the specific application, ensuring a high level of filtration accuracy.

→ Ease of Maintenance

Easy cleaning and maintenance, minimizing downtime and ensuring continuous operation.

→ Versatility

Suitable for a wide range of applications, including industrial, commercial, and residential water systems.

Discover the world of media purification, where precision and purity set new standards, ensuring the highest standards of safety and reliability.

WHAT WE OFFER |

✔️ Improved Media Quality

✔️ Healthier Living Environments

✔️ Extended Equipment Lifespan

✔️ Enhanced Process Efficiency

✔️ Environmental Protection

✔️ Regulatory Compliance

✔️ Cost Savings

Discover Excellence |

Explore Our Filtration Product Portfolio

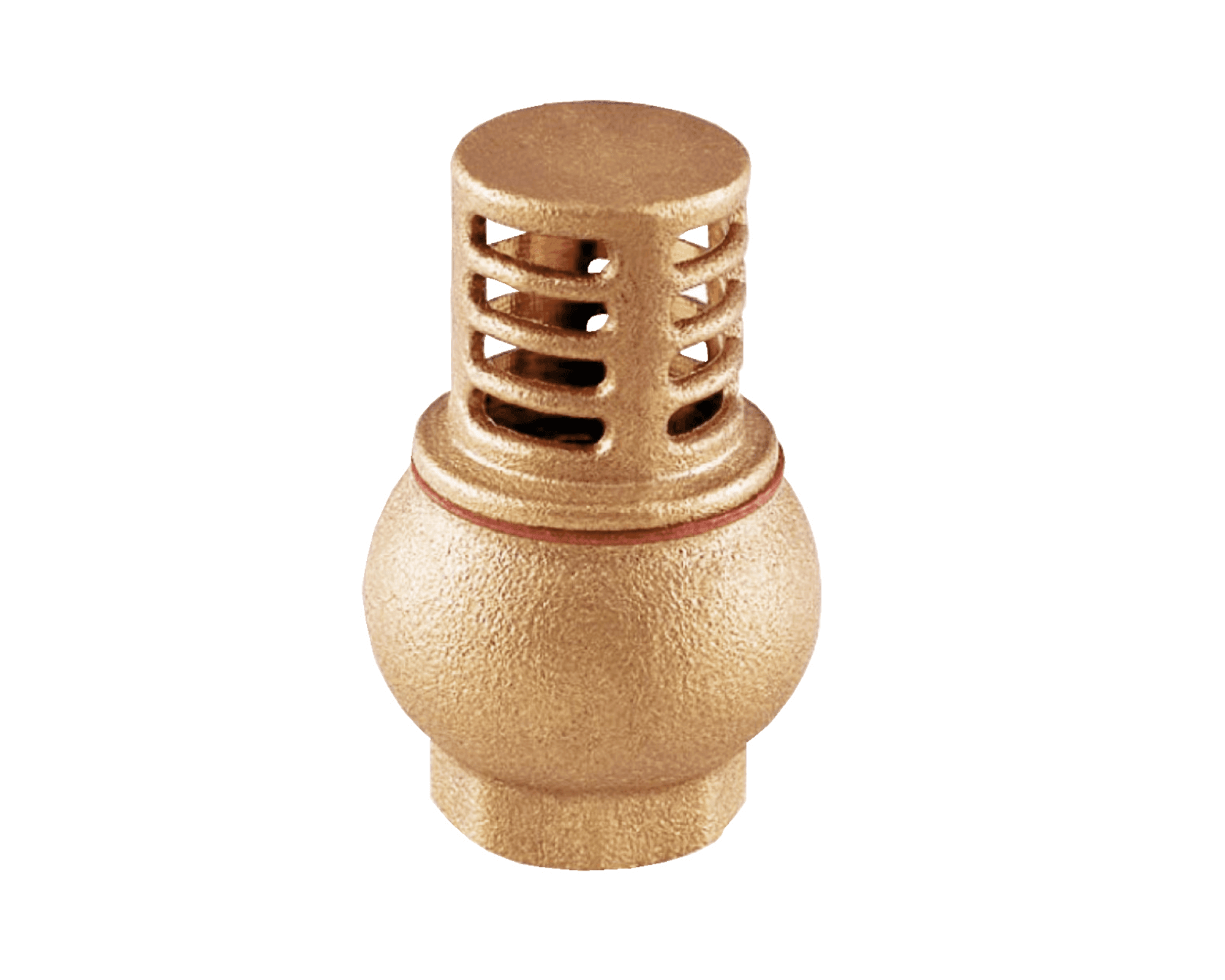

Foot valves

| Check valve

| Filtration

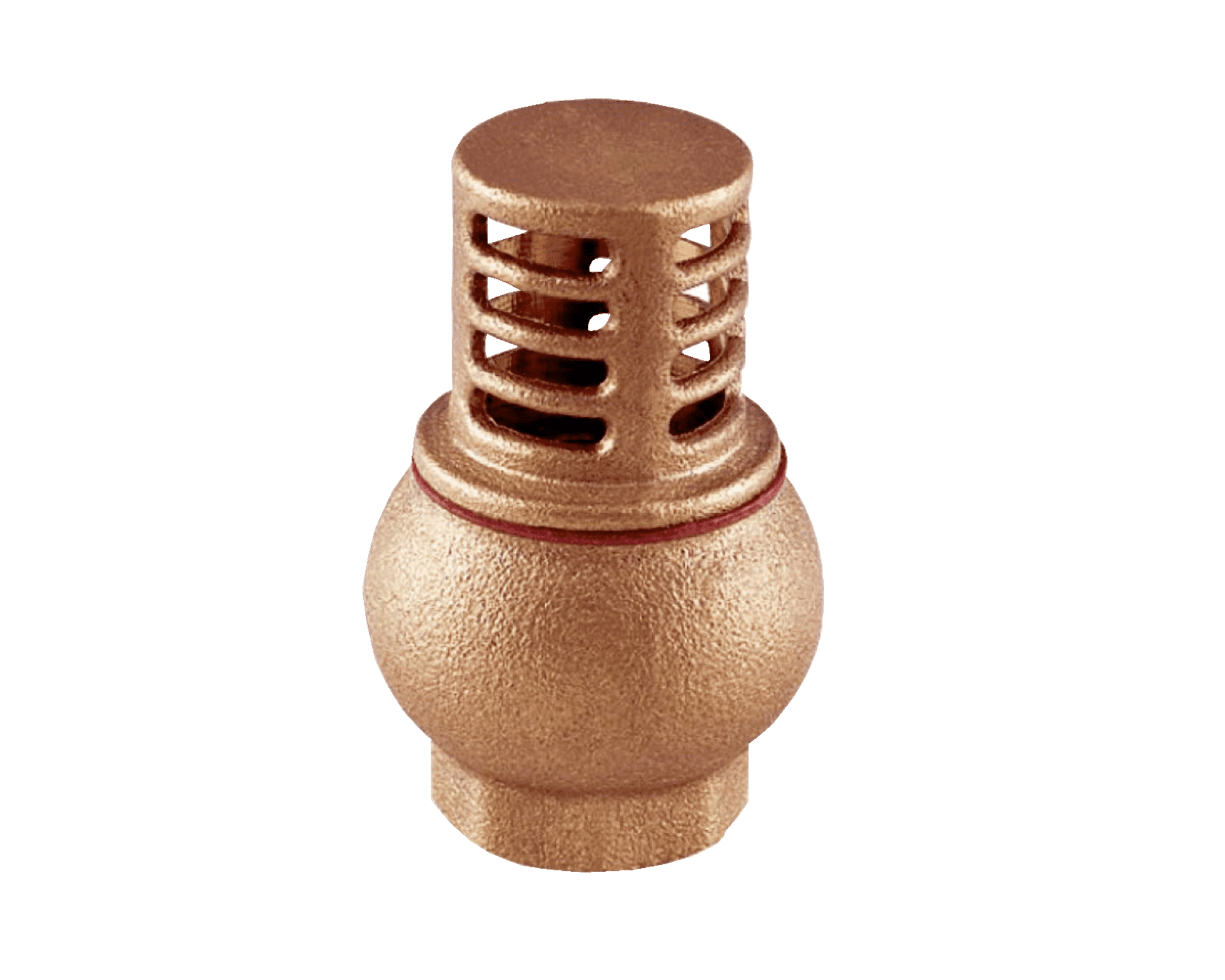

Suction diffuser

| Flow stabilizer

| Filtration

Understanding Filtration.

Y-Strainers are essential in water treatment and other media treatments, removing solid particles and sediments to ensure clean and clear media. They work by trapping contaminants like rust, scale, and other debris, improving media quality for a variety of applications.

In Y-Strainers, the fluid passes through mesh screens designed to capture specific pollutants. These mesh screens can vary, but they all aim to provide cleaner media, whether drinking water or other uses.

The importance of Filtration.

Y-Strainer filtration is vital for public health, environmental sustainability, and industrial efficiency. By removing solid particles and sediments, Y-Strainers protect downstream equipment, ensuring efficient and reliable flow operation.

In addition, Y-Strainers help reduce pollution, and protect natural resources. In industrial settings, they improve process efficiency, extend equipment life, and enhance reliability, contributing to economic growth and environmental care.

Overall, Y-Strainer filtration is essential for its technical benefits and for promoting purity, health, and sustainability, ensuring clean media for various applications.

Exploring Mesh Screens

Mesh screens in Y-Strainers are key to capturing contaminants and maintaining fluid purity.

There are three main types of mesh screens, each with unique filtration capabilities:

→ Perforated Screens

Made by punching holes in a stainless steel sheet, these screens provide initial filtration by allowing fluid to pass while trapping larger particles.

→ Mesh Screens

These screens use a woven pattern of fine stainless steel wires to capture contaminants. The mesh size, indicated by the number of holes per inch, determines the filtration accuracy.

→ Wire Mesh Varieties

Available in plain woven and Dutch weave patterns, these screens offer different levels of filtration efficiency. The plain woven pattern is simple, while the Dutch weave is more complex for better filtration.

Different mesh types are available within these categories, each suited for specific filtration needs and fluid characteristics.

Terms and definitions

MESH

The number of openings per inch (25.4 millimeters) of the screen. More meshes mean a finer screen.

MICRONS

The micron rating indicates the smallest particle size (in microns) that the filter can remove. Understanding both mesh size and micron rating is important for accurate comparisons. As mesh size increases, micron rating decreases.

Applications for Y-Strainers

Y-Strainers are used in a wide range of applications including potable water applications, industrial processes, and non-potable water applications.

Y-Strainers are versatile and can be customized to meet the specific needs of different industries and applications. They can handle various pressures and temperatures, making them suitable for both high and low-pressure systems.

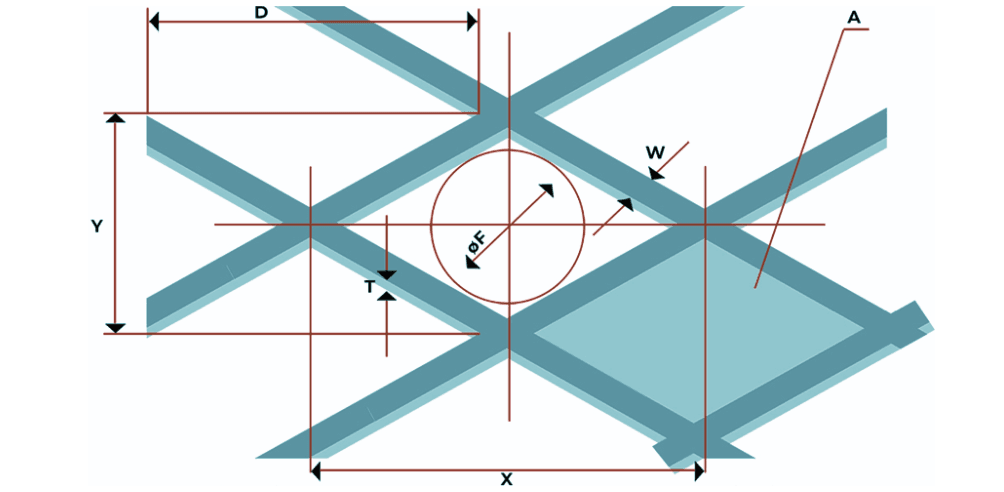

Understanding Filtration Screen Measurements

Understanding the complexities of screen specifications is paramount in selecting the optimal filtration solution for your needs. From mesh count to wire thickness, each measurement plays a crucial role in shaping the performance and effectiveness of filtration systems.

In this guide, we unravel the mysteries behind filtration screen measurements, c.f. the below image:

ST: Screen type

Mesh: Number of holes per linear inch

øF: Inscribed hole diameter

T: Wire thickness

D: Wire diameter

W: Wire width

A: Area of each hole

Y and X: Wire space at the X-axis and Y-axis

Need assistance?