| SATURATED STEAM APPLICATION

Navigate the Power of Saturated Steam with Precision Engineering

Harness the full potential of saturated steam in your industrial applications with our cutting-edge valves. Designed for optimal performance, our valves offer precise control, efficiency, safety, and reliability in the most demanding environments.

The Heartbeat of Steam Control | Key features

→ Maintain system pressure

→ Control temperature

→ Ensure safety

→ Optimize efficiency

With our specialized solutions for saturated steam applications, we don't just offer reliability — we guarantee it.

WHAT WE OFFER |

✔️ Enhanced saftey

✔️ Eliminate disruption

✔️ Smoother operations

✔️ Regulatory compliance

✔️ Environmental stewardship

✔️ Extended equipment lifespan

Utilizing Saturated Steam Power

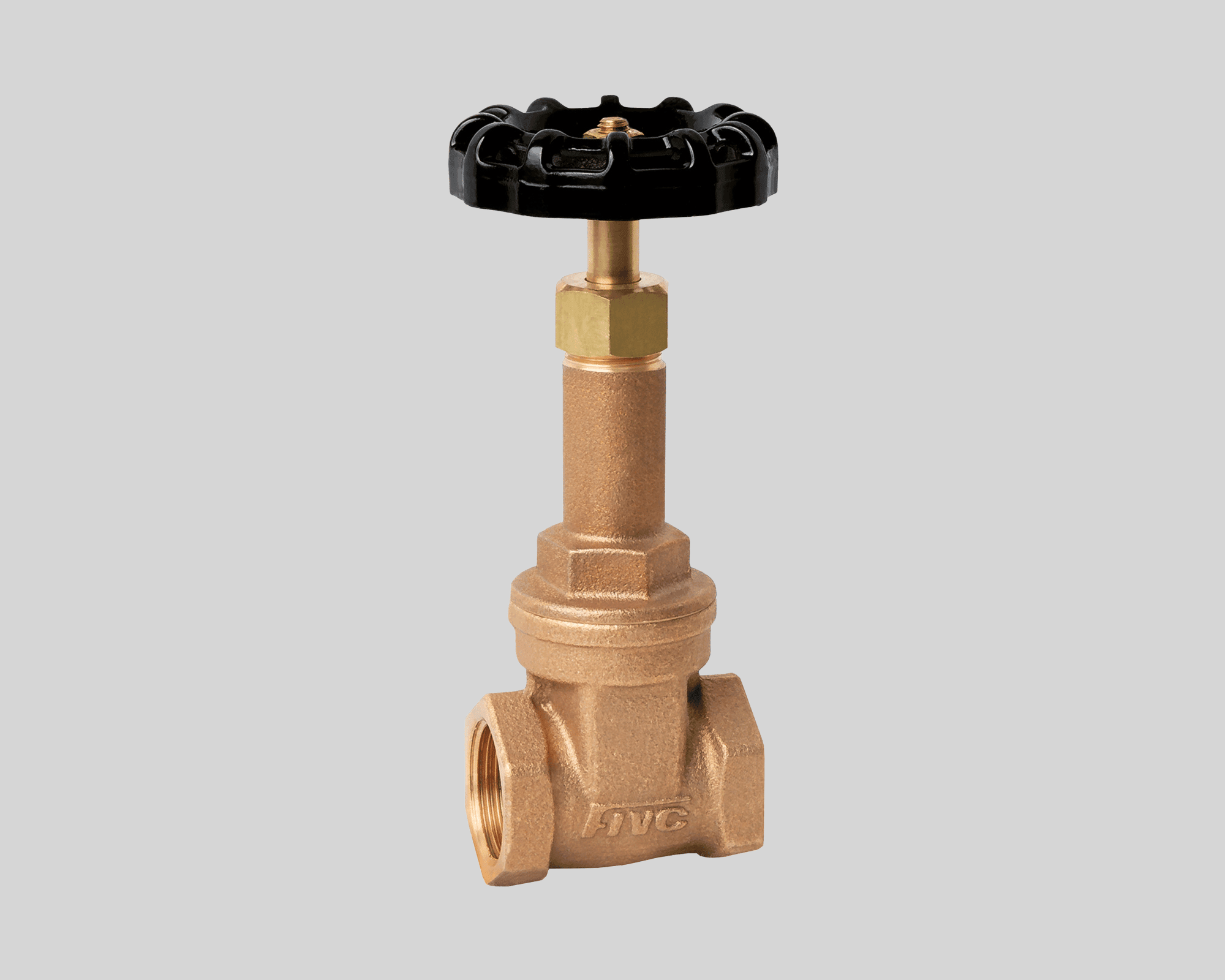

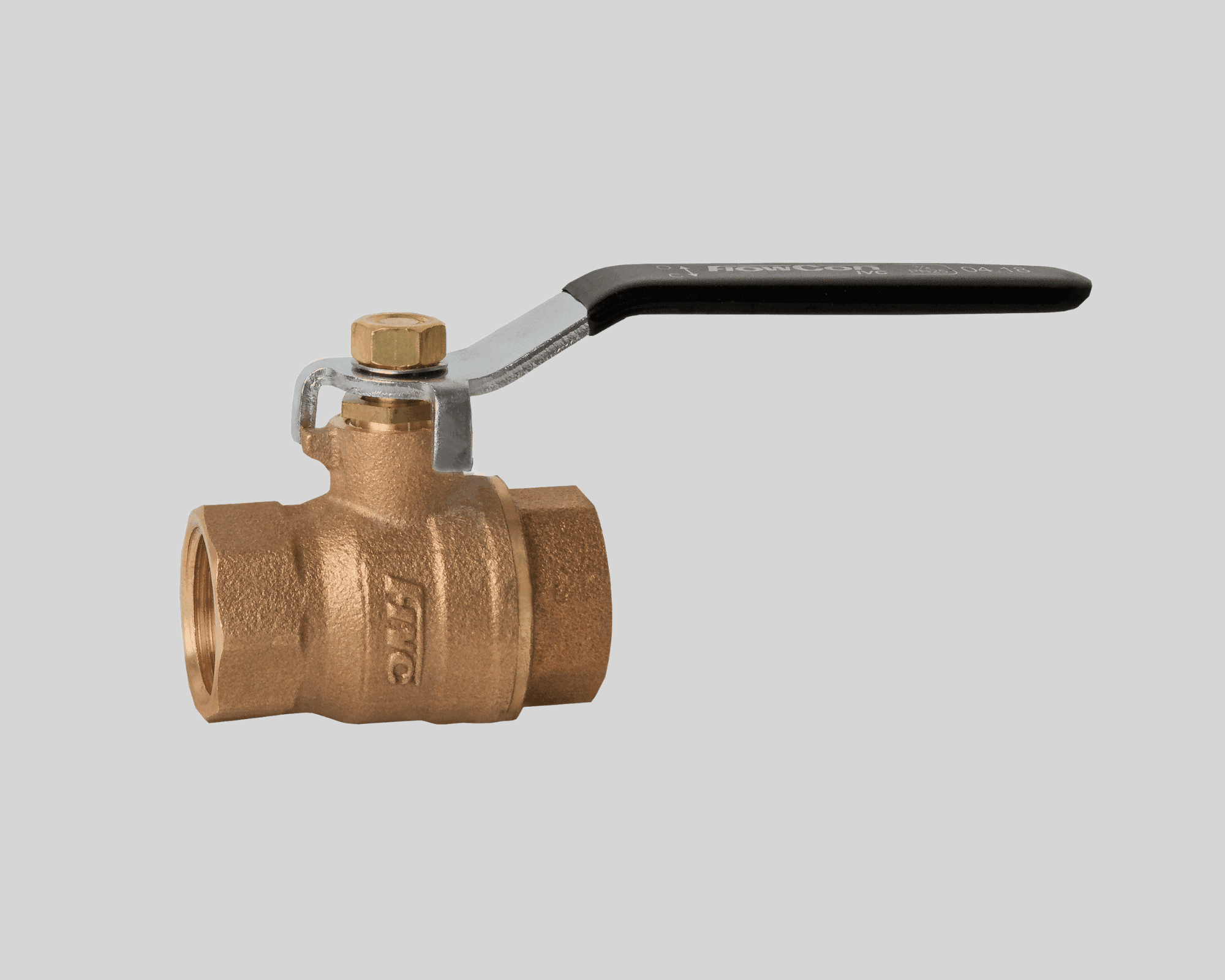

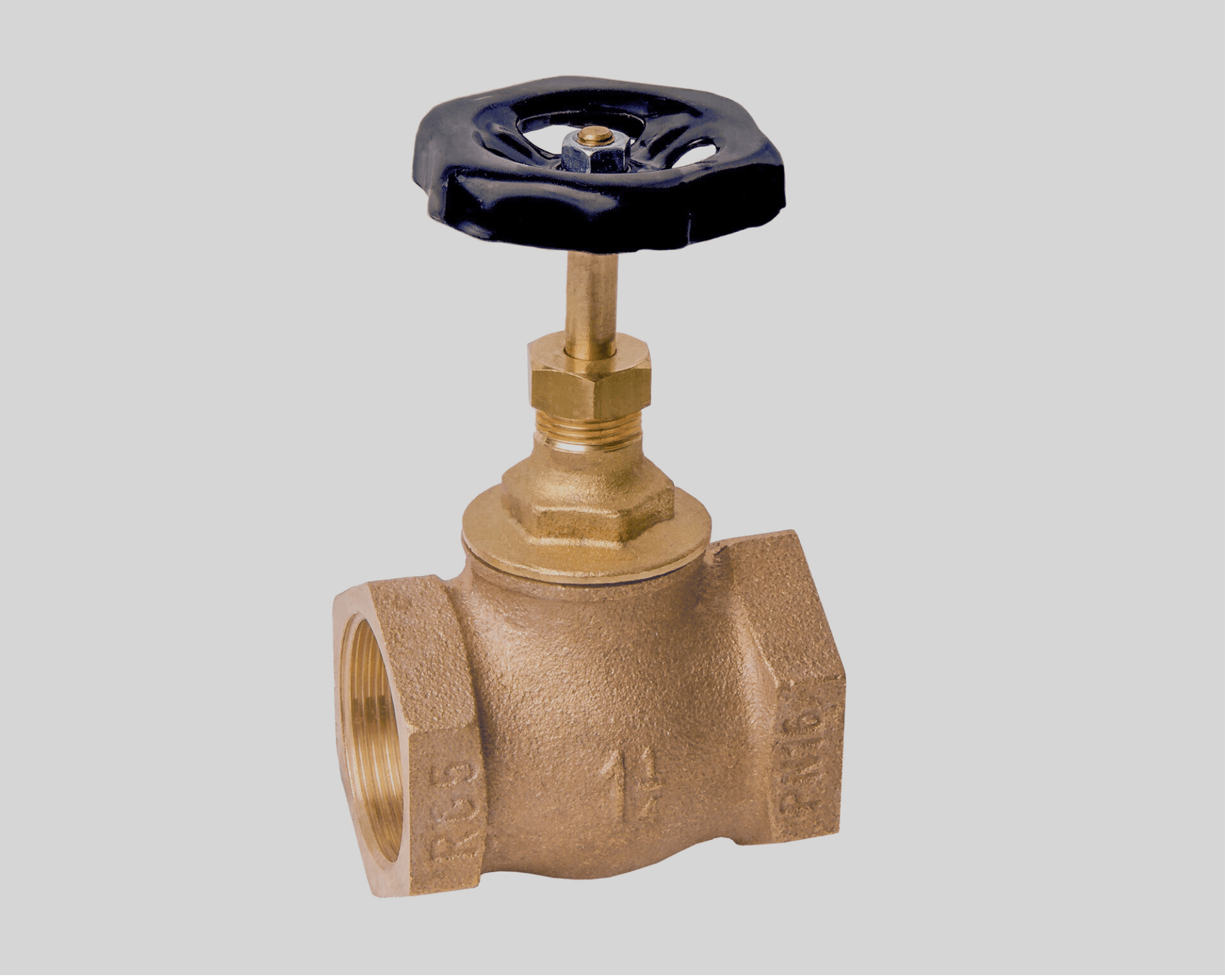

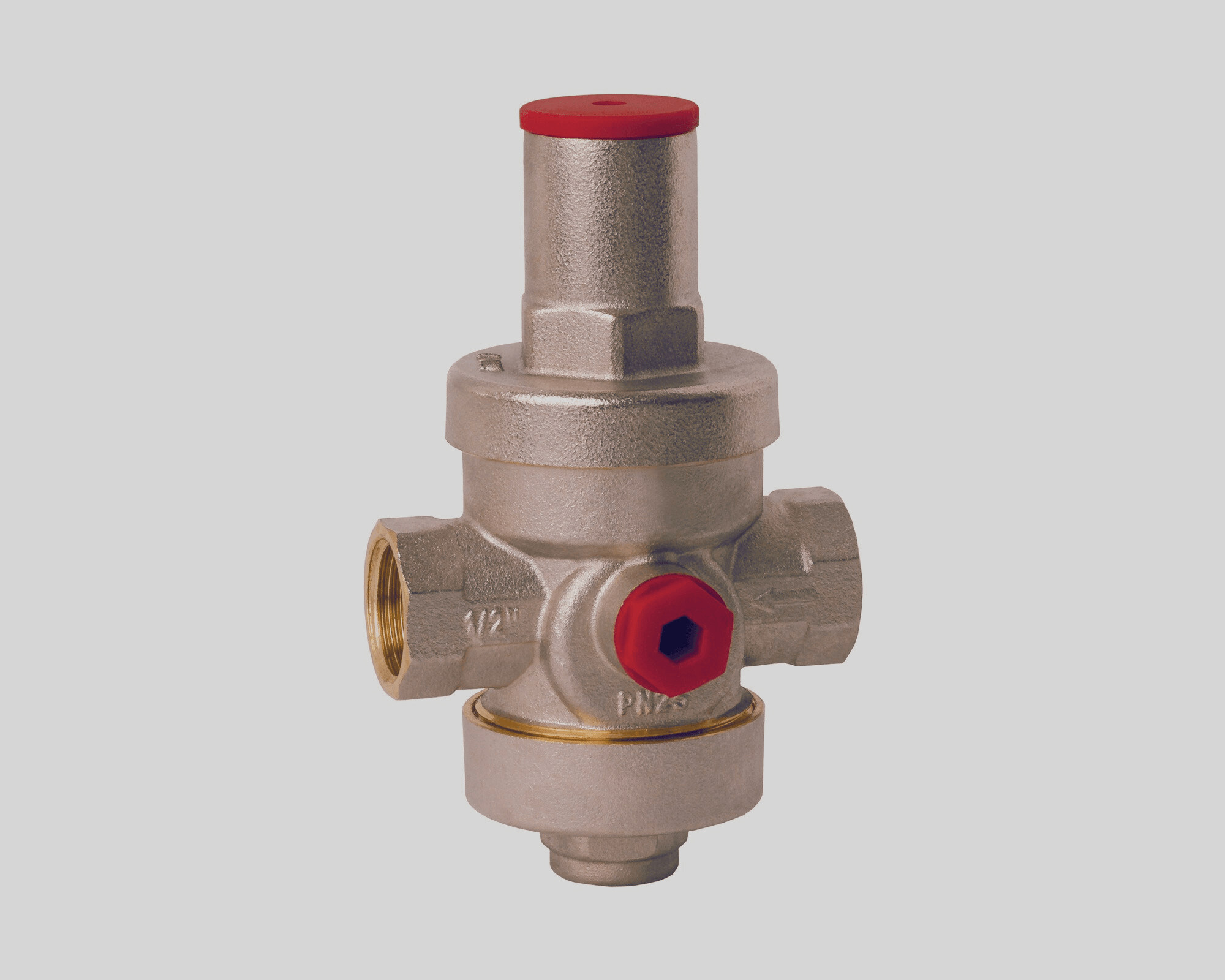

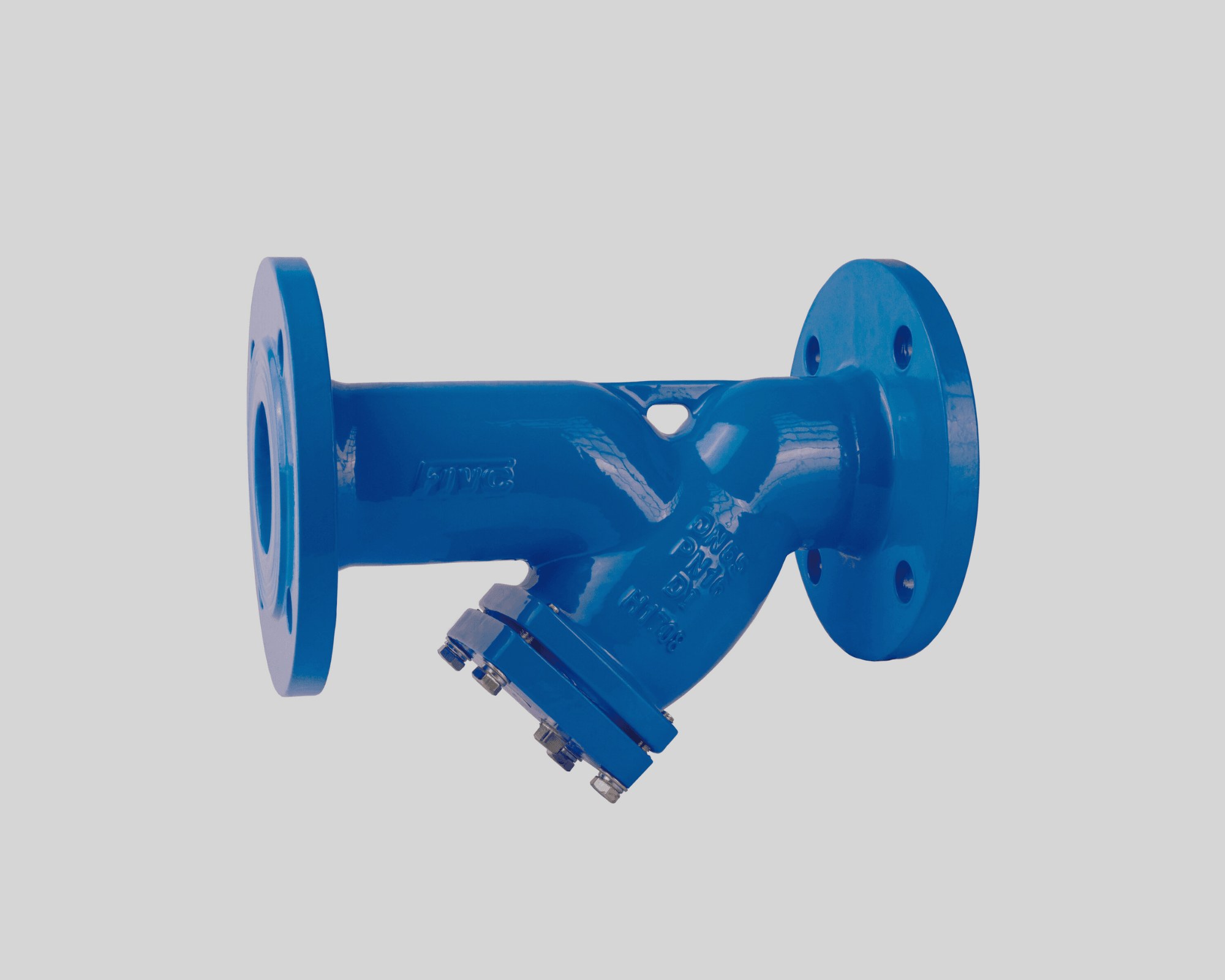

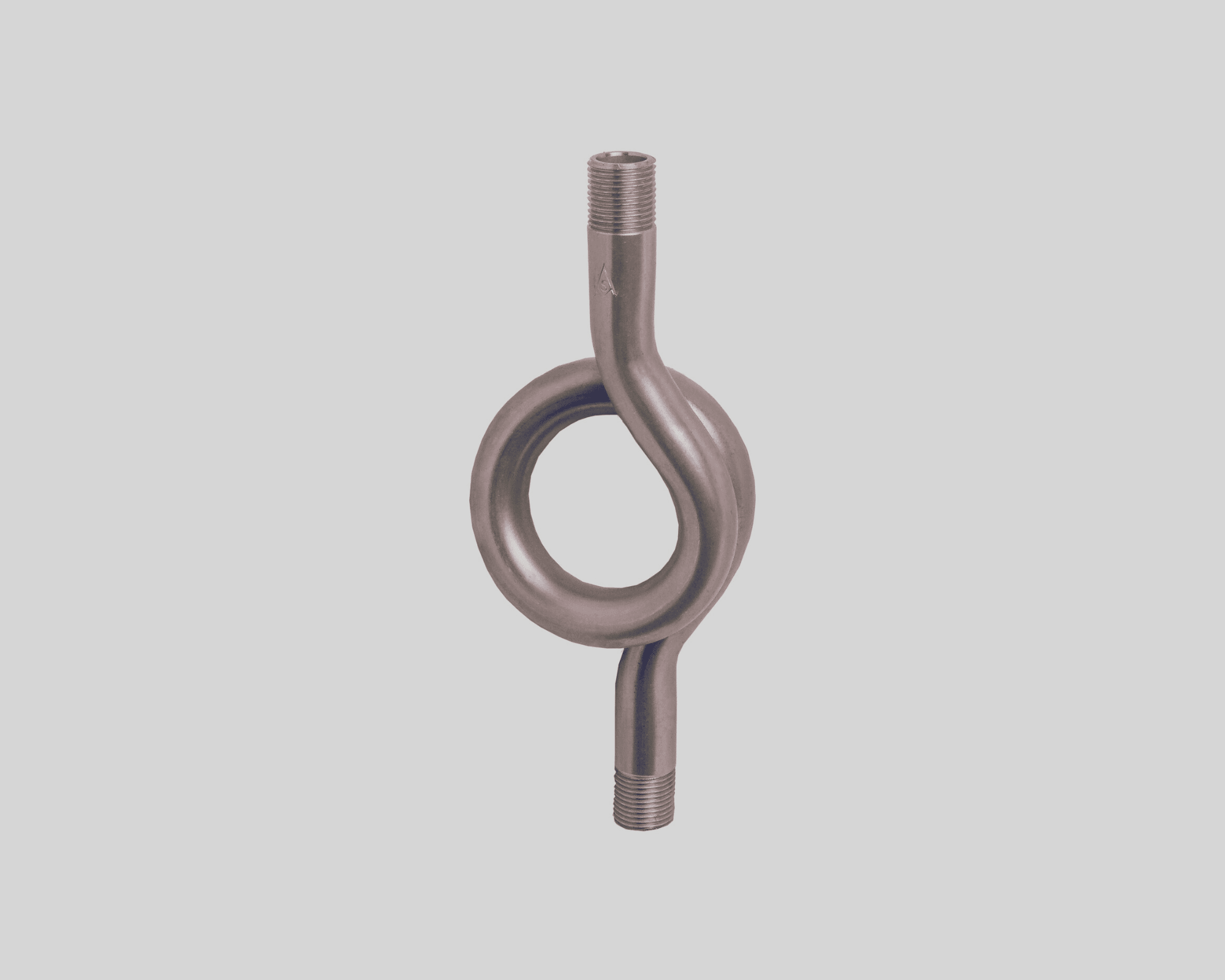

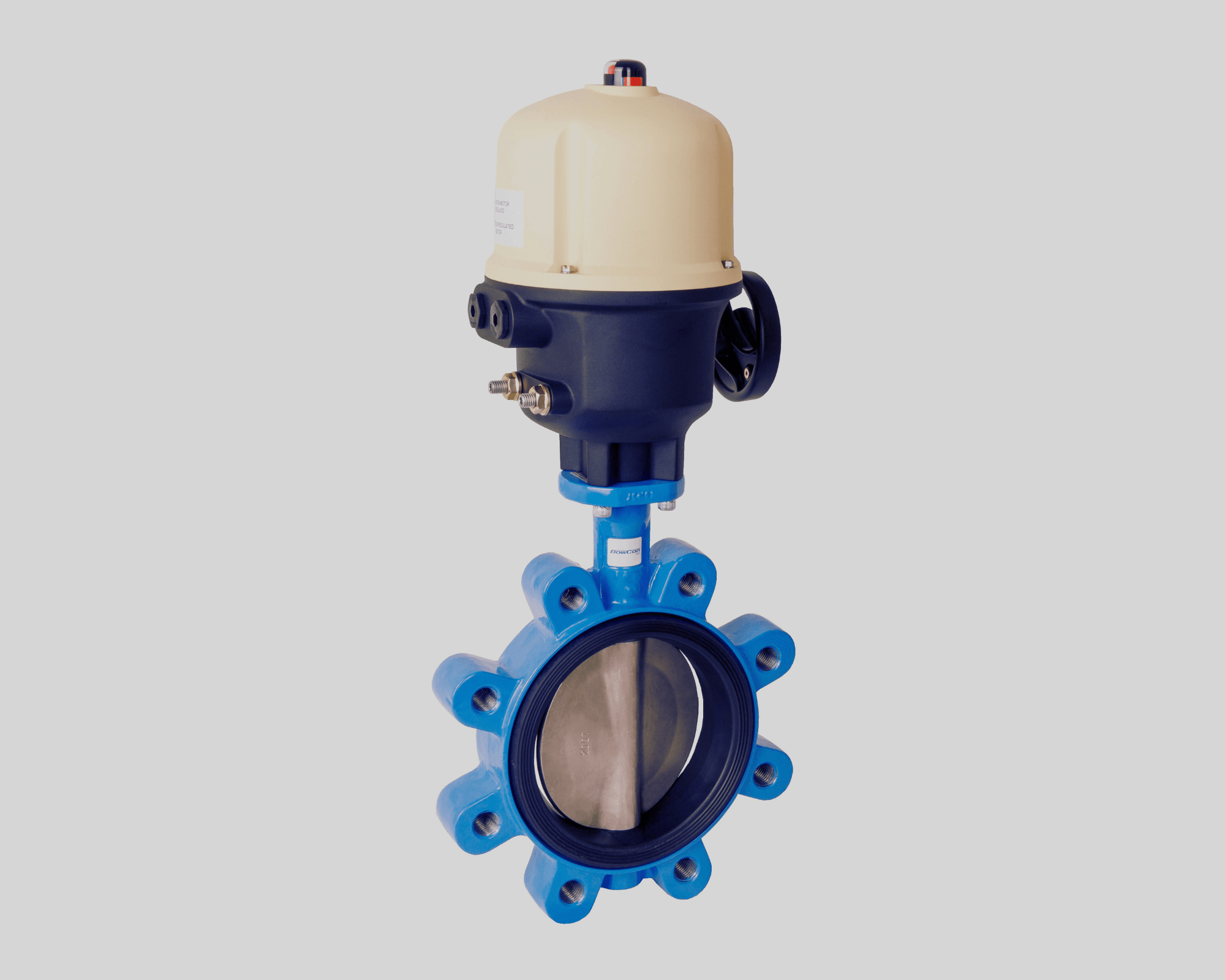

Explore Our Saturated steam Handling Solutions

Understanding Saturated Steam Applications.

Saturated steam applications play a pivotal role across various industries, powering essential processes and machinery. Central to the efficiency and safety of these applications is the accurate management of saturated steam flow.

Saturated steam flow control plays a crucial role as it directly influences productivity, reduces operational costs, and promotes environmental sustainability in application designs.

The importance of Saturated Steam application Control.

Controlling saturated steam flow is complex and involves managing flow rates, pressure and temperature at the saturation point to assure peak performance and safety.

Precision is crucial for achieving efficient steam utilization, minimizing energy waste, and maintaining system integrity.

Key Aspects of Controlling Saturated Steam Flow

Efficiency Optimization |

Proper steam flow control ensures that steam is delivered to where it's needed, when it's needed, optimizing energy usage and reducing operational costs.

Safety Assurance |

Upholding a stable flow of saturated steam helps avert pressure variances that could cause harm to equipment or pose safety threats, securing a safe operational setting.

System Integrity |

Accurate regulation of saturated steam flow is crucial to avoid condensate formation, water hammer, and other complications that could affect the efficiency and lifespan of steam infrastructure.

Process Consistency |

Stable saturated steam flow is essential for maintaining consistent temperatures and pressures, which is critical for the quality and reliability of industrial processes.

Energy Conservation |

Efficient saturated steam flow control minimizes energy losses associated with steam leaks, inefficient distribution, and overpressurization, contributing to sustainability efforts and cost savings.

Our valves are designed to meet the unique challenges posed by steam systems ensuring efficiency, safety, and sustainability.