Silencing Disturbances

| Vibration and Noise Reduction Solutions

Vibrations and noise can disrupt operations and compromise productivity in industrial settings. Effective vibration and noise reduction are critical for creating a productive and safe work environment.

Transform your work environment and eliminate disruptive vibrations and noise through our valve solutions. Ensure productivity flows effortlessly while safety remains at the forefront.

How Our Valves and Components Contribute

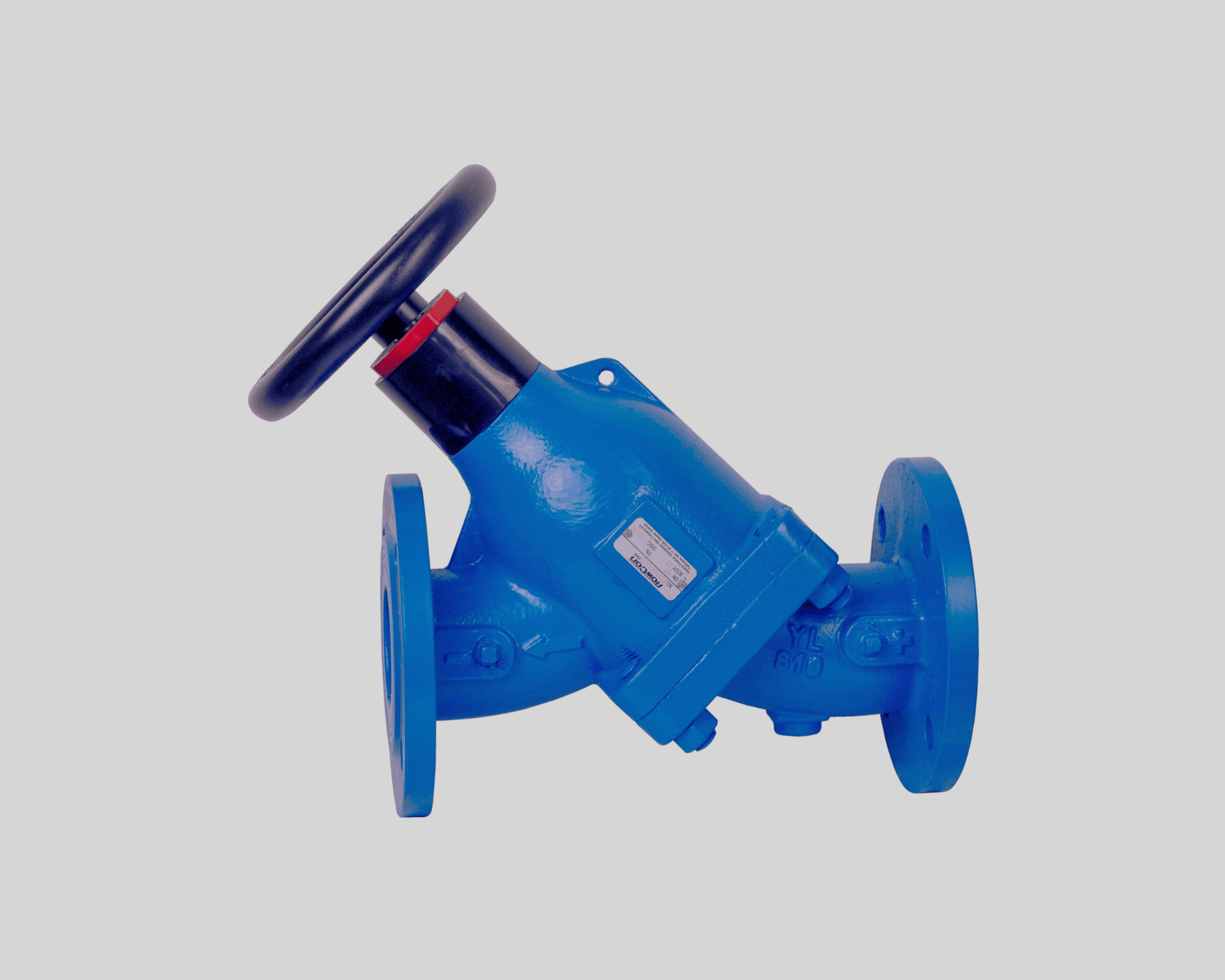

Absorb vibrations and noise generated by pumps and other mechanical equipment. They act as dampers, preventing vibrations from transmitting through the piping system and thus reducing noise

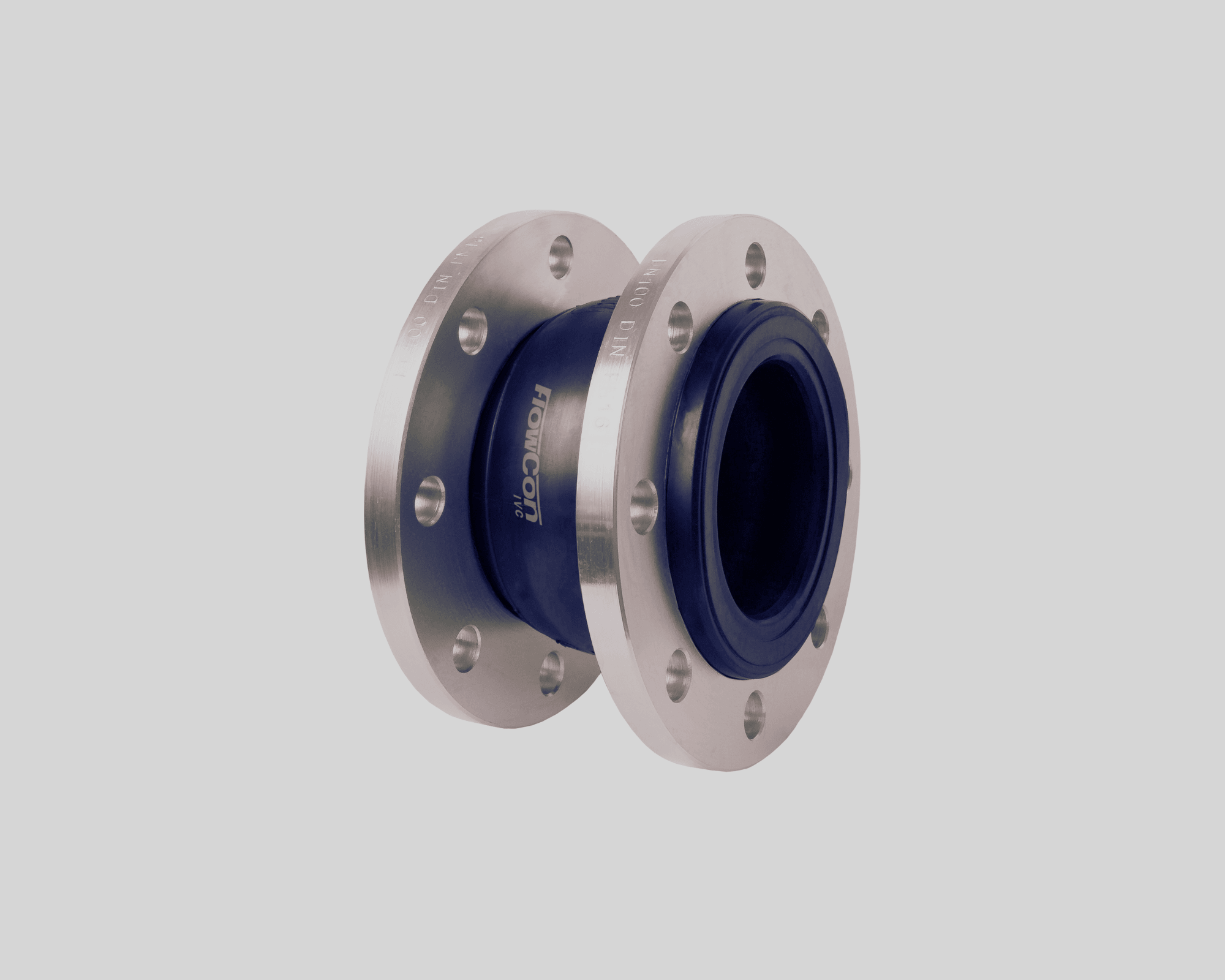

Designed to absorb thermal expansion, vibrations, and noise. They provide flexibility in the system, preventing stress and noise transmission caused by thermal movements and mechanical vibrations.

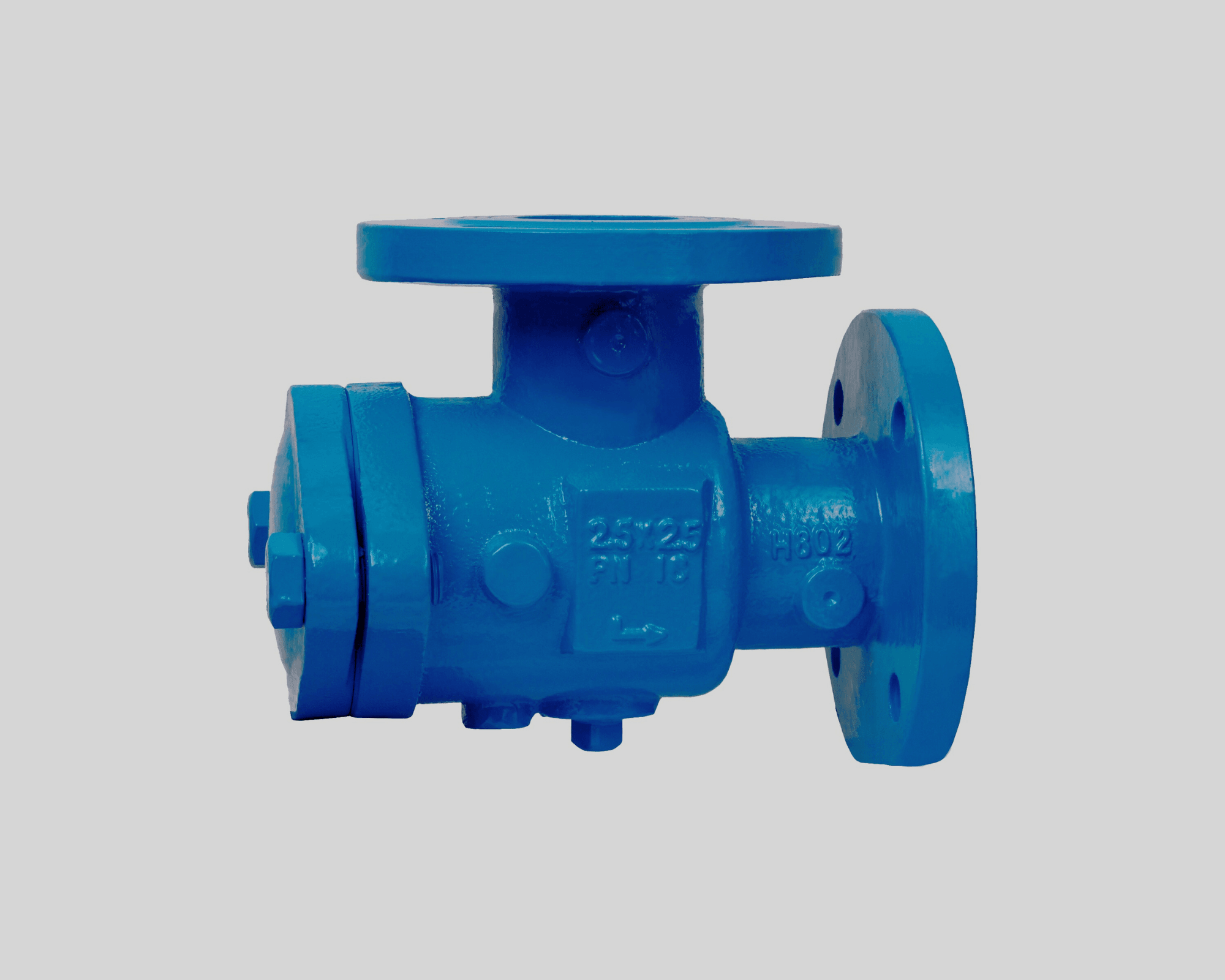

Prevent backflow, which can cause sudden pressure changes and vibrations. By maintaining a unidirectional flow, these valves help reduce noise and ensure smooth operation.

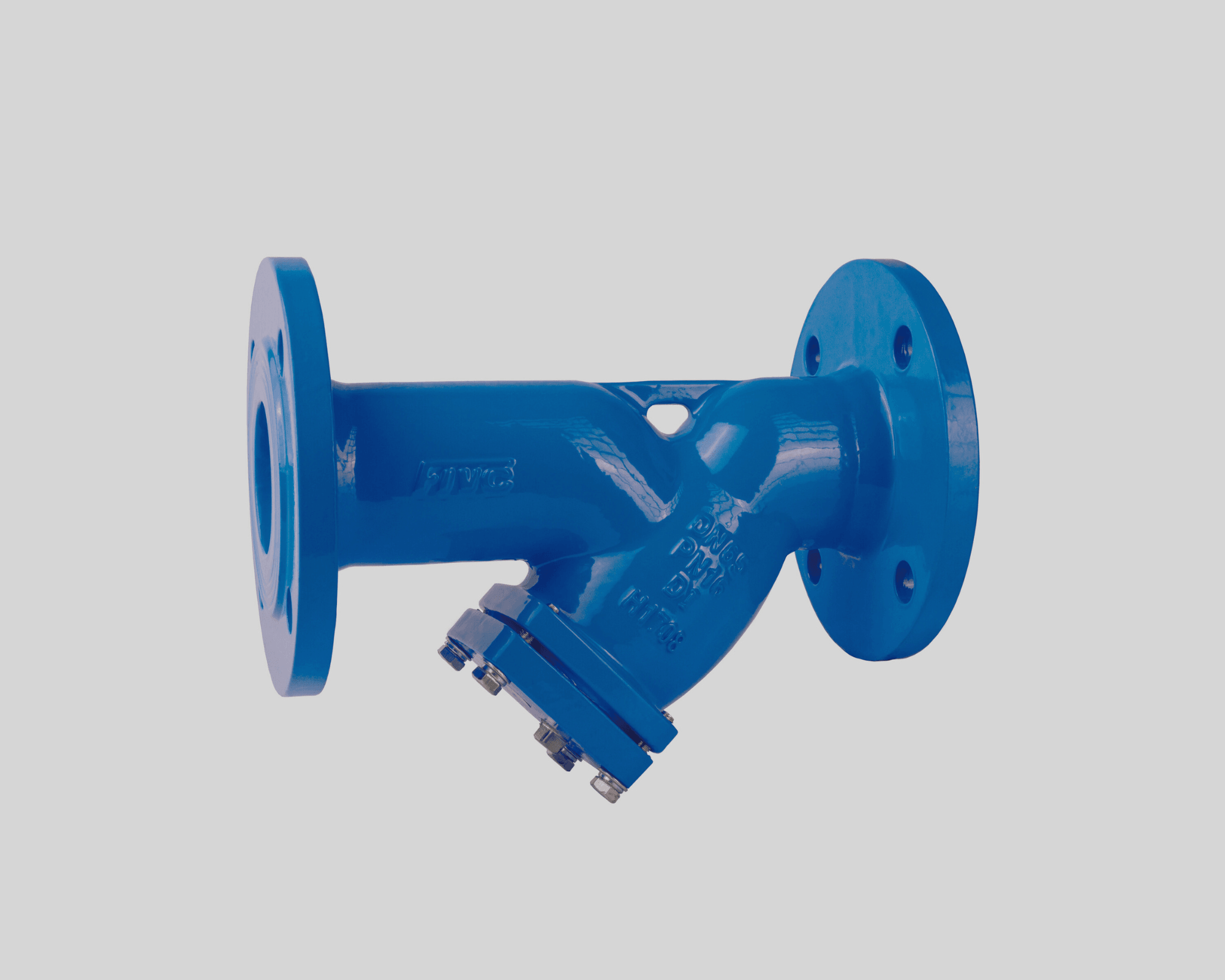

Remove debris and particles from the fluid, preventing clogging and potential vibrations caused by blockages. They ensure smooth flow, contributing to noise reduction.

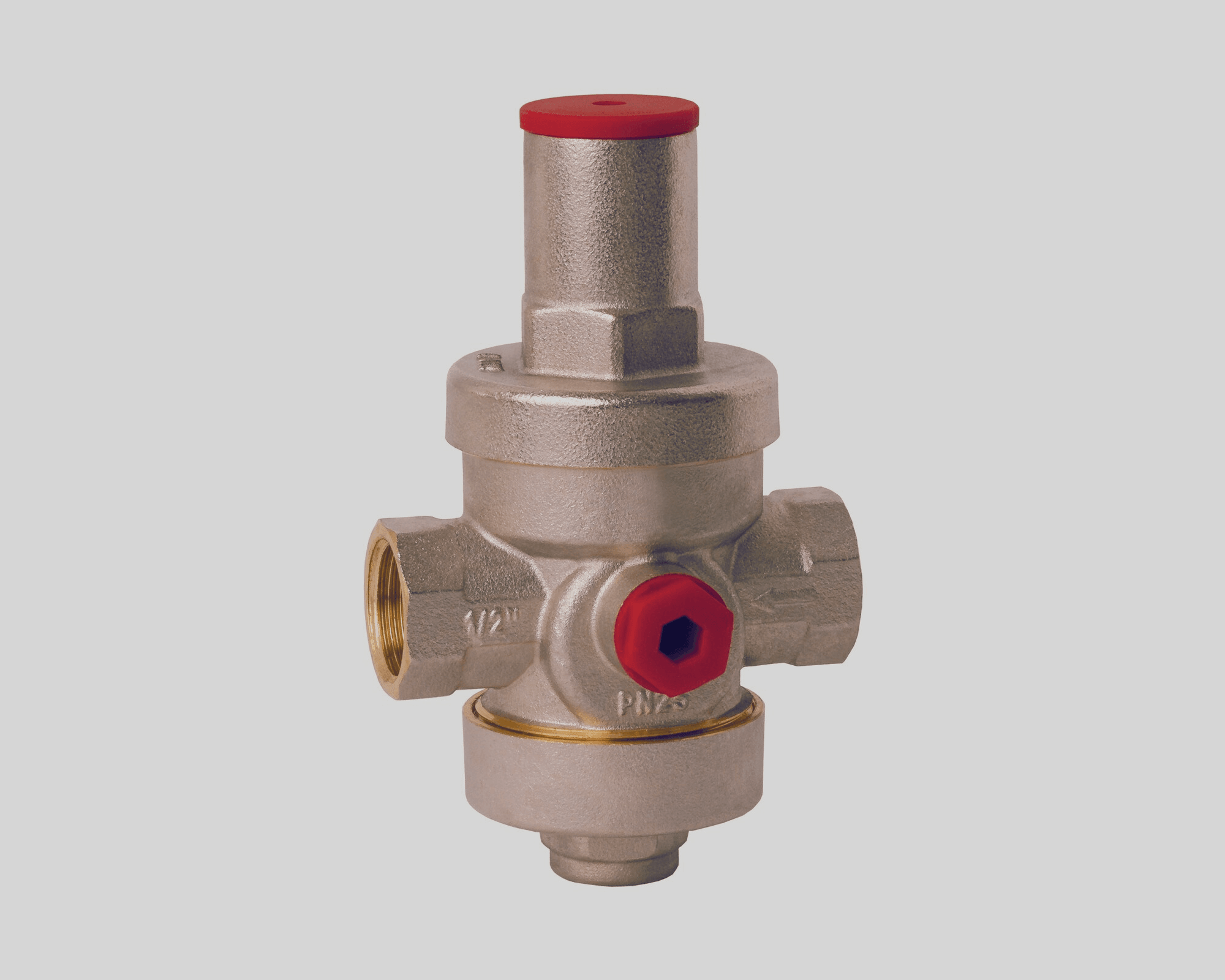

These maintain consistent pressure levels, reducing vibration and noise caused by pressure fluctuations. They also ensure a stable flow, contributing to a quieter and more efficient system.

Combine the functions of a check valve, balancing valve, and flow control valve. They optimize system performance, reduce turbulence, and minimize noise and vibration.

Provide a steady and even flow to pumps, reducing vibration and noise caused by turbulent flow conditions. They ensure the efficient operation of the pump and the overall system.

Unveil a world where disturbances fade into the background, replaced by the calm of efficiency and safety assurance.

WHAT WE OFFER |

✔️ Enhanced saftey

✔️ Eliminate disruption

✔️ Comfortable working environment

✔️ Smoother operations

✔️ Regulatory compliance

✔️ Environmental stewardship

✔️ Extended equipment lifespan

Unlock Harmony in Motion

Explore Our Vibration and Noise Reduction Solutions

Understanding Vibration and Noise.

Vibration and noise are common challenges in industrial settings, affecting everything from machinery performance to financial implications and worker safety.

What is Vibration?

Vibration refers to the back-and-forth movement of mechanical parts. In industrial settings, vibration can be caused by unbalanced rotating parts, misalignment, or irregularities in machinery operations. While some vibrations are standard, too much vibration can cause serious problems.

What is Noise?

Noise in industrial settings is typically unwanted sound that can interfere with normal operations. It is often a byproduct of vibrating machinery and can vary in severity, potentially causing a host of issues for both equipment and personnel.

Effectively managing these issues is crucial for maintaining operational efficiency and creating a safe work environment.

The importance of Vibration and Noise Control.

Exploring vibration and noise reduction is vital for optimizing industrial operations. Addressing the challenges mentioned below not only improves machinery performance and extends equipment life but also enhances worker safety and comfort.

→ Operational Efficiency

Excessive vibration and noise can disrupt machinery's smooth operation, leading to frequent breakdowns and inefficiencies. By minimizing these disruptive forces, we can ensure that machinery operates more smoothly, reducing downtime and enhancing overall performance.

→ Equipment Longevity

Vibration accelerates wear and tear on machinery, which can shorten its operational lifespan and increase maintenance costs. Effective vibration control helps maintain the integrity of equipment, thereby extending its service life and reliability.

→ Safety

High levels of noise and vibration can pose significant safety risks. Noise can distract workers, increasing accidents, while vibration can lead to mechanical failures that endanger personnel. Reducing these factors contributes to a safer working environment.

→ Worker Health and Comfort

Continuous exposure to high noise levels and vibrations can lead to health issues such as hearing loss, stress, and fatigue. Creating a quieter and more stable environment improves worker comfort and productivity, improving work satisfaction and efficiency.

→ Regulatory Compliance

Industries are often subject to strict regulations regarding permissible noise and vibration levels. Non-compliance can result in legal penalties.

Our advanced valves are engineered to reduce vibrations and dampen noise, ensuring smoother and quieter operations.

Implementing our effective vibration and noise control solutions not only enhances operational efficiency and reduces maintenance costs, but also promotes a safer and more productive work environment.