| Exploring Vibration and Noise Reduction Valves and accessories

Embracing Tranquil Efficiency

In the rhythm of industrial operations, vibrations and noise can disrupt efficiency, compromising productivity and safety.

Embracing Safety and Efficiency |

At the core of every fluid system, our vibration and noise reduction solutions promote efficiency, reliability, and safety. With their ability to dampen vibrations and silence disturbances, they ensure that operations flow smoothly, preventing disruptions, mitigating risks, and upholding workplace safety standards, maintaining system integrity.

Understanding the role and functionality of vibration and noise reduction solutions is paramount for optimizing fluid systems. From dampening vibrations in industrial processes to silencing disturbances in commercial applications, these solutions play a crucial role in enhancing operational efficiency and productivity.

Delve deep into the world of vibration and noise reduction solutions.

Discover the Vibration and Noise Control

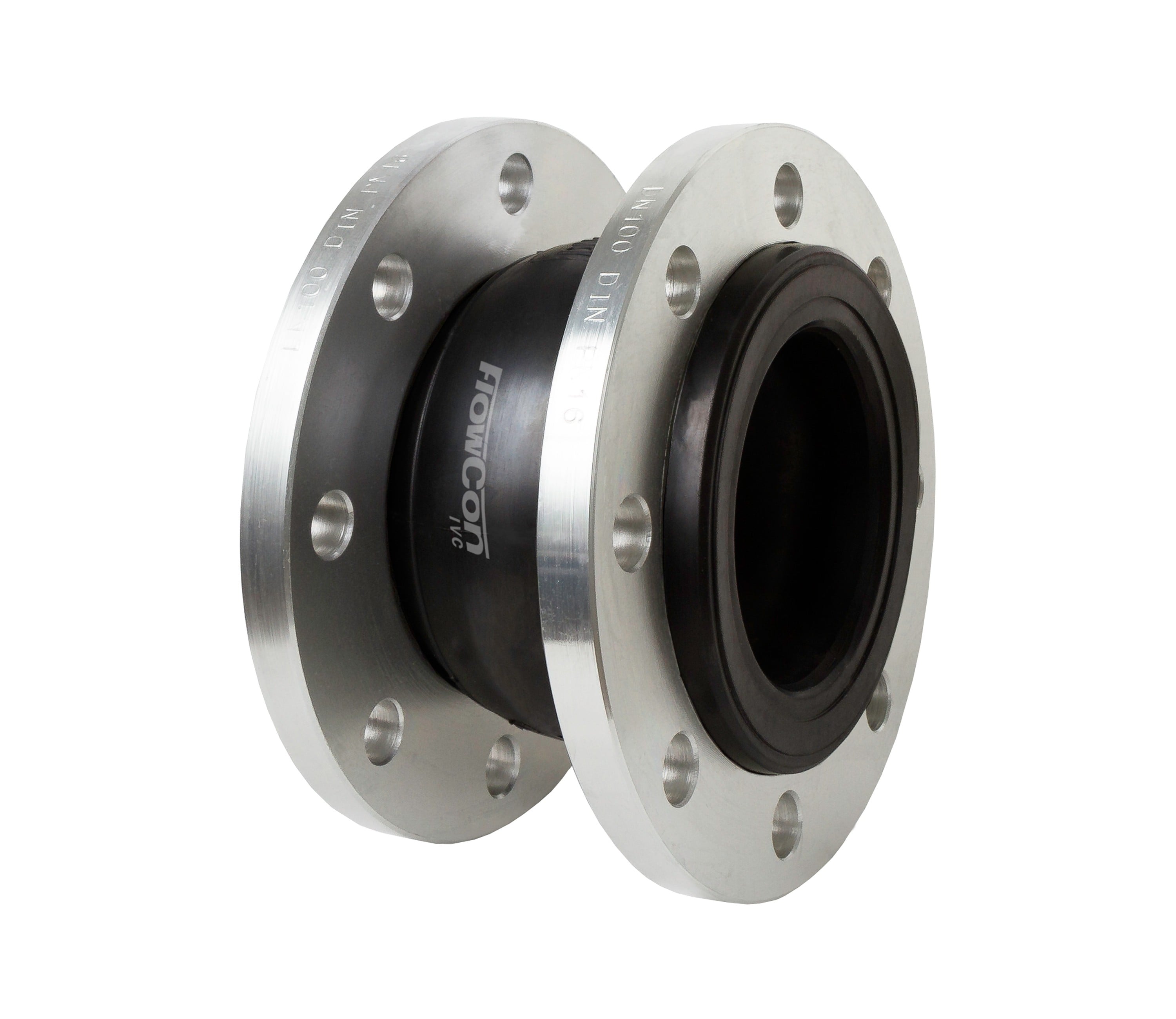

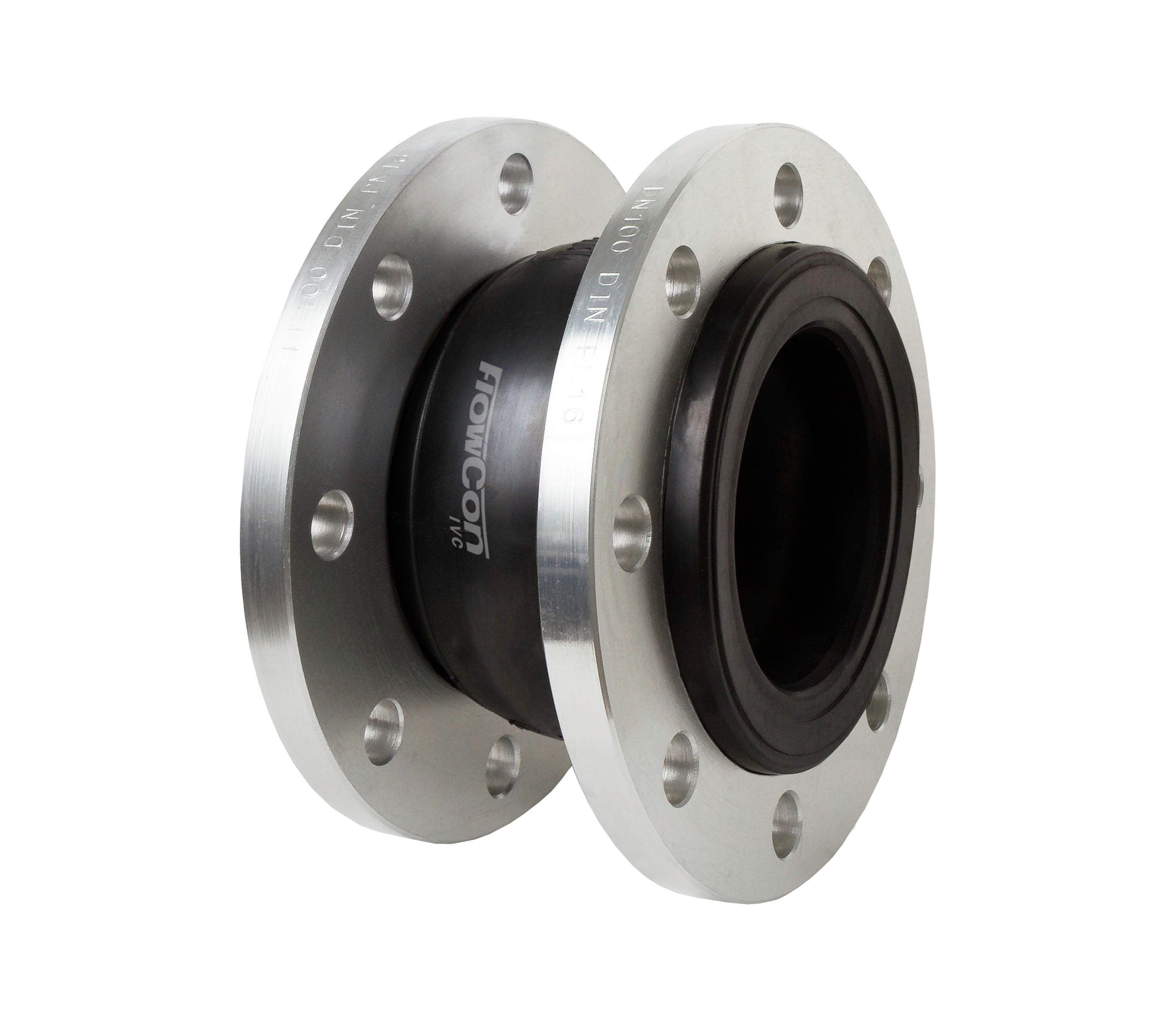

EXPANSION JOINTS |

Expansion joints offer flexibility and absorbing movements caused by thermal expansion, contraction, or vibrations. These joints act as buffers, dampening the effects of vibrations and minimizing the transmission of noise throughout the piping system. By absorbing shocks and movements, they prevent the propagation of vibrations that could lead to equipment damage, structural issues, or excessive noise levels.

✔️ Vibration dampening

✔️ Noise reduction

✔️ Preventing damage to equipment

✔️ Safer working environment

✔️ Improved system performance

FLEXIBLE HOSES |

Designed to absorb vibrations and dampen noise, ensuring smooth and efficient operations across various industries.

Flexible and adaptable to the dynamic movements within piping systems, rubber flexible hoses provide a cushion against disruptive vibrations, preventing transmission to adjacent components and structures.

✔️ Vibration absorption

✔️ Noise dampening

✔️ Safety enhancement

✔️ Optimized operations

✔️ Flexibility

CHECK VALVES |

Check valves play a critical role in maintaining system reliability by preventing backflow and ensuring consistent pressure levels. A silent check valve eliminates vibration and noise by using a spring-assisted closure that prevents slamming, ensuring a smooth shut-off without generating water hammer, which typically causes noise. In contrast, a dual plate check valve reduces water hammer moderately with its controlled, spring-assisted closure, limiting reverse flow and reducing noise and vibration, though not as effectively as silent check valves

✔️ Back-flow prevention

✔️ Pressure integrity

✔️ Reliability and efficiency

✔️ Versatile system

PRESSURE REDUCING VALVES |

Essential for maintaining consistent pressure levels, pressure-reducing valves regulate upstream pressure to protect downstream equipment and ensure system reliability.

✔️ Maintains Consistent Pressure

✔️ System protector

✔️ Prevents Water Hammer

✔️ Conserves Water and Energy

TRIPLE-DUTY VALVES |

Combining the functionalities of check valves, shut-off valves, and balancing valves, triple duty valves offer unparalleled versatility for a wide range of flow control applications.

✔️ Optimized Flow Control

✔️ Space and Cost Savings

✔️ Versatile system

Straight type

STRAINERS |

By removing debris from fluid streams, strainers prevent clogs and pressure fluctuations. They directly impact system performance and reliability

✔️ Debris management

✔️ Equipment protection

✔️ Improved process efficiency

✔️ Regulation compliance

SUCTION DIFFUSERS |

3-in-1 valve, combining a strainer, flow straightener, and a diffuser, suction diffusers enhance pressure control in pump suction lines. While not as common as other components, they play a valuable role in pressure control applications.

✔️ Flow conditioning

✔️ Pressure loss reduction

✔️ Enhancing system reliability

✔️ Improving system efficiency